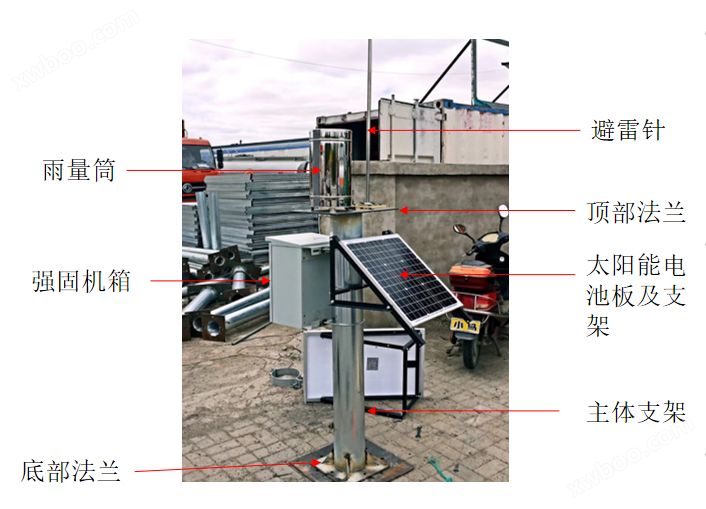

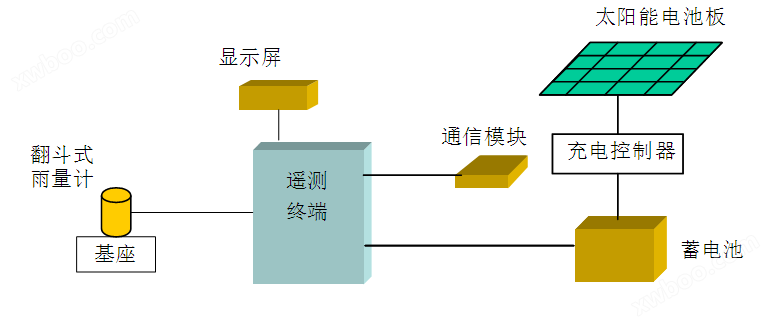

The automatic rainfall station is mainly responsible for automatically sending the data collected by the rainfall sensor to the information collection platform through a communication transmission channel according to the set working system. Using telemetry terminals as the core, equipped with tipping bucket rain sensors, communication terminals, power systems, and lightning protection systems, to achieve automatic collection and transmission of rainfall information. The overall structure is shown in the following figure:

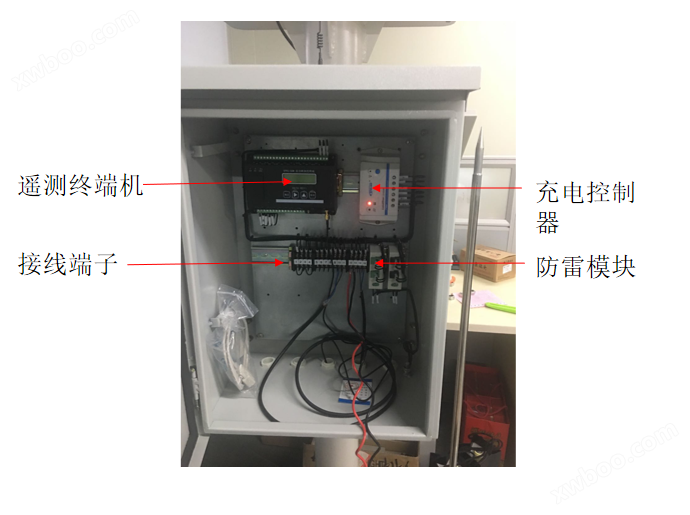

The automatic rainfall station mainly consists of a tipping bucket rain gauge, telemetry terminal (including manual setting), GPRS/GSM communication module, data card (including flow), display screen, battery (38AH), solar panel (40W) and charging controller, lightning protection system (lightning rod, down conductor, lightning grounding, etc.), rain gauge base and installation, integrated cabinet, and strong chassis.

Product Features

The automatic rainfall station adopts a management mode of manned and unmanned, realizing the automatic collection and transmission of rainfall information. Adopting a hybrid working system of timed self reporting, event reporting, and response. The automatic rainfall station should have a dual transmitter function and be able to automatically provide feedback on its operating status.

(1) The resolution of the tipping bucket rain sensor is 0.5mm, and it sends once per minute when there is rainfall, and does not send when there is no rainfall, which efficiently saves the traffic cost required for reporting. The sending process includes the rainfall process and is stored locally in solid state;

(2) The Ping An report is sent once a day at 2 am, 6 am, 8 am, 14 pm, and 20 pm, including battery voltage, signal strength, and other related information;

(3) It has the functions of manual counting, remote and on-site parameter setting, and can transmit some special data such as simple messages to the central platform through the manual counting device;

(4) Capable of responding to instructions from the central station;

(5) Can send data through the primary and backup channels in a timed or event self reporting manner, and automatically switch to the backup channel for transmission when the first transmission channel is unavailable;

(6) The working condition report function can send the operating parameters of the equipment in real time to the central station through the main and backup channels to determine the overall operation of the equipment;

(7) Support multiple sending functions on one platform.

| Equipment name | Main technical parameters |

| Tipping bucket rain gauge | Inner diameter of rainwater inlet: Φ200mm ; Rainfall intensity measurement range: 0.01-4mm/min; Measurement error of tipping bucket: ≤± 4%; Working temperature: -10 ℃~50 ℃ Environmental temperature:- 40℃~60℃ |

| Remote telemetry terminal (including manual setting) | Can simultaneously access (RS232, RS485) interfaces, supporting public network (GSM/GPRS/CDMA/3G/PSTN) and satellite channels; Storage temperature: -35 ℃~+60 ℃, relative humidity 90%, no condensation |

| GPRS/GSM communication terminal | Working temperature: -40 ℃ to+60 ℃; Frequency: 900/1800/1900 MHz frequency band; Protocol: Supports SMS mode: GSM 07.07,GSM 07. 05; GPRS mode: GSM 07.60 and 07.07 ver 7.5.0; |

| Data card (including data usage) | 3G directional data card |

| Battery (38AH) | Maintenance free battery, capacity: 38AH; Discharge: -45 ℃~50 ℃ Charging: -20 ℃~45 ℃ Storage:- 30℃~40℃ |

| Solar panel (40W) and charging controller | Monocrystalline silicon solar cell modules, working and storage temperature -40 ℃~+60 ℃; Working environment temperature -25 ℃~50 ℃ |

| lightning protection system | The lightning protection grounding body adopts 63 × 63 × 6mm national standard galvanized angle steel, and the grounding wire adopts 40 × 4mm national standard galvanized flat steel. |

| Rain gauge base | Rod type rainfall facility. Composed of foundation and columns. Column: made of galvanized steel pipe |

| Integrated cabinet | Customization: The cabinet and fixing screws are made of stainless steel material and galvanized as a whole |

| Strong chassis | RTU chassis, including signal lightning protection and power lightning protection facilities |

| fence | The zinc steel guardrail is treated with electrostatic spraying technology on the surface, and its main material is hot-dip galvanized pipe. |